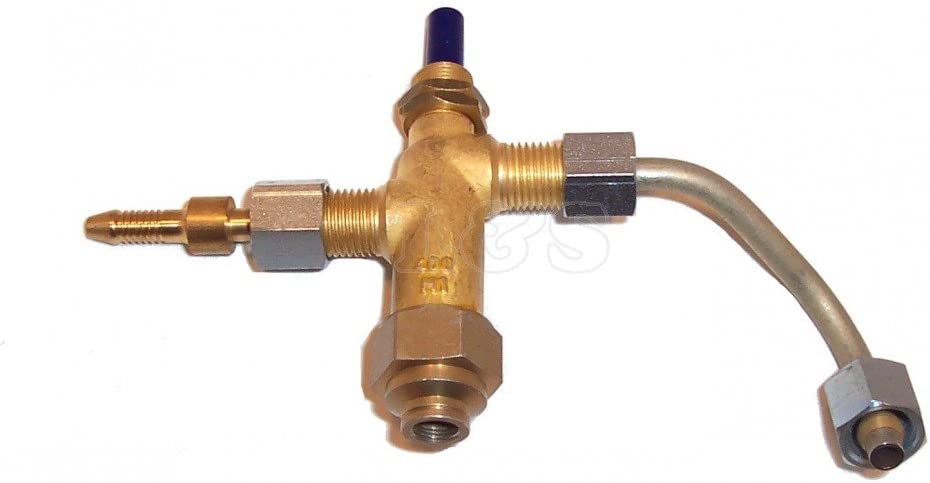

A flame supervision device (FSD) is a safety device that is used to monitor the presence of a flame in a combustion system, such as a furnace, boiler, or other heating equipment. The purpose of an FSD is to detect the presence of a flame and shut down the system if the flame is not present, in order to prevent the release of potentially hazardous gases into the environment.

FSDs typically use optical or ultraviolet sensors to detect the flame, and they can be integrated into the control system of the heating equipment. Some common types of FSDs include flame rods, flame detectors, and ionization sensors. These devices are an important component of the overall safety system of a heating system, and they help to ensure that the system operates safely and efficiently.

From a safety perspective, flame supervision devices are generally considered to be good inventions. They help to ensure that equipment is operating safely and can reduce the risk of fire, explosion, and other hazardous incidents. They can also help to protect workers and the environment from the effects of such incidents. However, from a practical perspective, the use of a flame supervision device may also increase the cost of operation and maintenance of equipment, as well as add complexity to the process. The device may not always be necessary, depending on the type of equipment and the operating conditions.

Are Flame Supervision Devices Prone to Failure?

Flame supervision devices are designed to monitor the presence of a flame in a combustion process and shut down the fuel supply in the event of a flame failure. While these devices are typically reliable and play an important role in ensuring the safe operation of equipment, it is possible for them to fail.

The causes of failure in flame supervision devices can be varied, ranging from electrical issues, such as a faulty wiring or a damaged control circuit, to physical problems, such as a clogged nozzle or a broken sensor. In some cases, the failure of the device can be caused by improper installation or maintenance, such as not regularly cleaning the device or not properly calibrating it.

In order to minimize the risk of failure, it is important to properly install and maintain flame supervision devices. This may include regularly cleaning the device, conducting regular inspections and tests, and replacing any damaged or worn components. Additionally, it is important to regularly review and update the operating procedures and safety protocols to ensure that the device is being used as intended.

In the event of a failure, it is critical to take prompt action to address the issue and prevent further damage. This may involve shutting down the equipment, identifying the cause of the failure, and repairing or replacing the device. In some cases, it may also be necessary to evacuate the area to ensure the safety of workers and the public.

Overall, while flame supervision devices are designed to be reliable and provide a critical safety function, it is important to be aware that they can fail and to take the necessary steps to minimize the risk of failure and ensure safe operation.